KNIFE VALVES

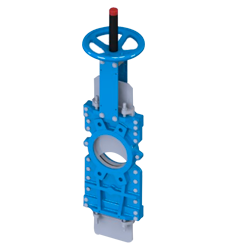

Manufactured in a single cast block with internal guides to guide the sash, with wedges that help the sash to close the body-seat, Unidirectional and Bidirectional, Wafer / Lug connection that allows high flow capacity and low pressure drop .

Its design in the form of a stepped transition prevents the accumulation of solids in the closure. Its design of the gate with rounded edges: prolongs the functional period of joints and packings.

Sectors:

RULES:

- DIN PN10 / PN16 / PN25

- ANSI 125/150

- Other manufacturing standards on request.

RANGE:

- DN50 (2”) – DN250 (10”) 10bar

- DN300 (12”) – DN450 (18”) 6bar

- DN500 (20”) – DN600 (24”) 4bar

- DN700 (28”) – DN1200 (48”) 2bar

MATERIALS:

- BODY: GG25, GGG40, GGG50, A216 WCB, CF8 (SS304), CF8M (SS316), 254SMO, SS310, SS904…et

- SEAT: EPDM, NITRILE (NBR), SILICONE, VITON, GRAPHITE, FLUCAST, TEFLON (PTFE)

- KNIFE: SS304L, SS316L, SS316TI, SS310S, SS904L, 254SMO, HARDOX…et

- PACKING: SYNT + PTFE, pure PTFE, GRAPHITE, CERAMIC … et

- O-THREAD: EPDM, NBR, SILICONE, VITON..et

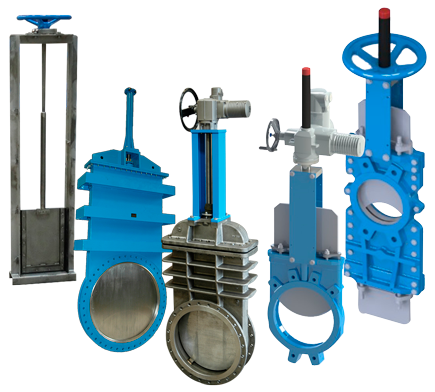

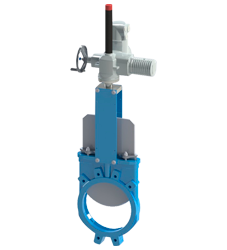

OUT KNIFE VALVES

GENERAL INDUSTRIAL KNIFE VALVE

THROUGH KNIFE VALVE

HIGH PRESSURE KNIFE VALVE

SILO KNIFE VALVE

MECHANICAL WELDED KNIFE VALVE

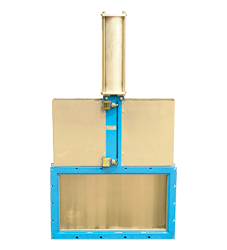

SQUARE KNIFE VALVE

CHANNEL WALL KNIFE ALVE

LANDFILL WALL KNIFE VALVE