Engineering and Design

CONCEPTUAL ENGINEERING

In URVA we have extensive experience in the Design of New Processes and in the evaluation of modifications of existing ones.

On some occasions, it is necessary to carry out a Conceptual Engineering in order to identify if the project is really feasible in our facilities, or if the equipment or processes that we need exist in the market.

Under these conditions, the typical scope of a Conceptual Engineering would encompass:

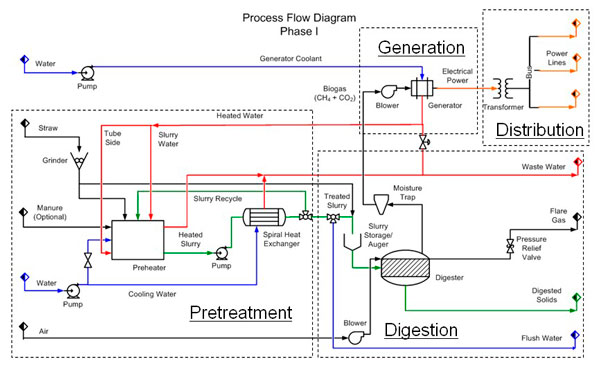

- Definition of the process at the PFD level.

- Preliminary Balance of Matter and Energy.

- Definition of the main equipment and analysis of its availability in the market.

- Basic definition of the project at electrical and instrumentation level.

- Embedding of the preliminary implementation in the area planned for it.

- Identification of the necessary Services.

- Preliminary project planning.

- Preliminary cost.

BASIC ENGINEERING

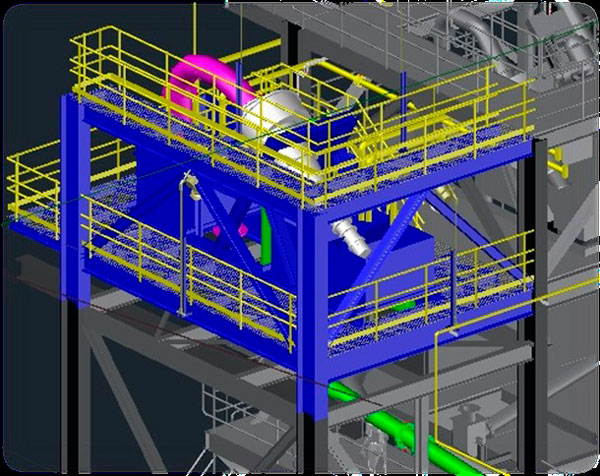

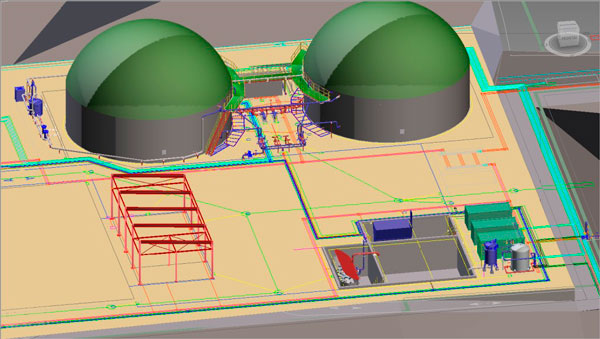

URVA develops these services in an important variety of sectors, among which we can highlight the Oil Refineries, Chemical and Petrochemical Plants, Mining, Thermal Power Plants, Combined Cycles, Biomass Plants and Cement Plants. For this we have software such as Autocad Plant 3D.

On the other hand, the types of jobs we develop cover a wide range, necessarily adapted to the needs of the client given the characteristics of this type of studies:

Basic Engineering of a Project, includes:

Complete development of the Process Engineering of the Unit:

- Process flow diagrams (PFD’s)

- Pipes and instruments diagrams (P&ID’s)

- Lists and Data Sheets of equipment

- Design and specification of equipment, containers and storage tanks

- Dynamic equipment specification

- Lists and Data Sheets of Valves and Instruments

- Sizing and specification of control and safety valves

- Preliminary development of the project in the rest of the disciplines of engineering

- Preliminary implementation plans

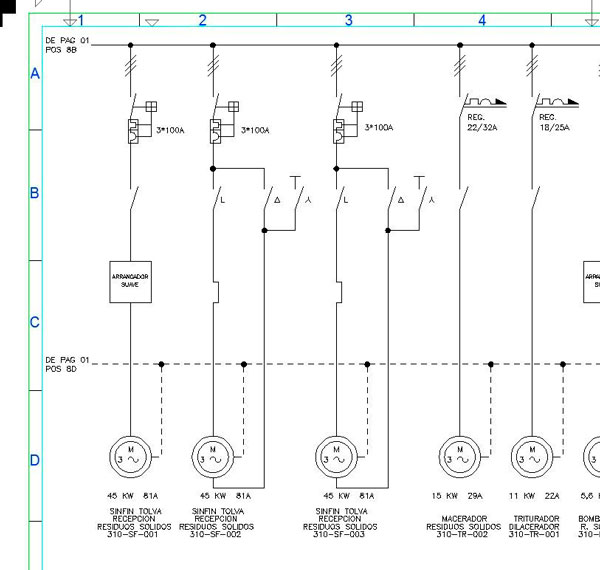

- Preliminary Electric Scheme

- Classification of Areas with Fire and Explosion Risk. ATEX Studies

- Project Planning

- Simulations of processes, with the corresponding execution of balances of matter and energy, as well as the calculation of properties or characteristics demanded by the client

Basic design of process equipment:

- Reactors

- Distillation columns

- Absorption towers

- Adsorption equipment

- Heat exchangers

- Evaporators

- Hydraulic and pipe system calculations

- Ovens and boilers

- Miscellaneous equipment: Dryers, filters, crystallizers …

- Drying and biomass grinding systems

Studies of technical and economic viability of process modifications.

Technical and economic evaluation of changes in operation or operating conditions.

Analysis of production processes: Identification and preparation of proposals to eliminate bottlenecks

Revamping studies of existing units.

Development of monitoring programs for process and production conditions, either through simulation or execution of specific applications.

Execution of Test-Run in production units.

Preparation of operation manuals based on processes developed by the client or on demand.

Validity studies / checking of torch systems.

Simulation and performance / efficiency studies or identification of problems in specific equipment: Exchangers, air coolers, pumps, compressors, piping systems, reactors, distillation columns, among others.

DETAIL ENGINEERING

URVA, it conforms to the values and specifications of basic engineering, performing detailed engineering according to standards, respecting the rules of art, safety.

The detailed engineering, is adjusted to the basic engineering (admitted correct), it is always advisable before starting this stage, to submit the basic engineering to a careful review, detecting the observations that deserve, and proposing the improvements that correspond.

Detailed engineering, must be done according to standards, rules of art, and safety criteria, all this must also be discussed conveniently at the beginning of this work

In this stage, the information provided by the basic engineering is converted into the detailed design of the work, in order to allow the purchase and construction of its constituent elements, and its assembly in a correct manner, meeting the technical requirements of the installation.

It is integrated in detailed engineering: drawings, spreadsheets, sketches, calculation memories, technical specifications, in such a way as to allow the contractor to carry out the indicated works.

Detail engineering includes, for the case in hand, the development of the construction project and the installations of the different disciplines, electricity, architecture, civil works, structures, etc.

Detailed engineering is based on basic engineering, taking the indicated guidelines and developing construction drawings.

It has as a new variable the precise definition of the equipment to be assembled (which has already been acquired), that is to say it has certified drawings of the same, and as manufacturing progresses, the drawings become conform to manufacture.

The documents that are issued in the detailed engineering stage are:

- Drawings

- Calculation memories

- Technical specifications

- Material sheets

- Test reports

Planification and control

- Purchasing management

- Activation of orders

- Construction supervision

- Start-up

- Administrative authorizations

- Construction + guarantees

Disciplines

- Process engineering

- Technologies

- Civil engineering

- Mechanical engineering

- Electrical engineering

- Instrumentation and control

- Integration and management

- Energy

- Special designs in 2D and 3D

- Electronic models

- I+D+i

- Project financing